|

NEWS RELEASE I 28 JULY 2025

NEW GRAPHITE TARIFF ENVIRONMENT UNDERSCORES KASIYA'S GLOBAL SIGNIFICANCE

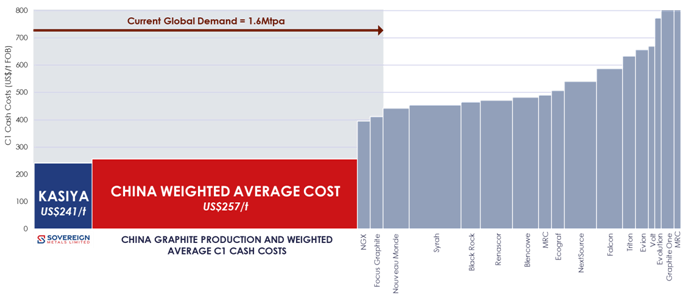

· Strategic positioning enhanced as new tariff environment highlights Kasiya's potential as world's largest and lowest-cost non-Chinese graphite producer with industry-leading US$241/t incremental cost of production

· Market dynamics impacted by new U.S. Commerce Department 93.5% anti-dumping duties on Chinese graphite imports

· Kasiya offers supply chain diversification opportunity as battery manufacturers seek alternatives amid 160% effective tariffs on Chinese-sourced graphite

· Latest coating optimisation testwork achieves successful CSPG production characteristics with superior performance metrics to support advancing offtake discussions

Sovereign Metals Limited (ASX:SVM; AIM:SVML; OTCQX: SVMLF) (Sovereign or the Company) is pleased to announce that at a time of unprecedented disruption in global graphite markets, with new U.S. tariffs fundamentally altering supply chain dynamics, the latest testwork on graphite from the Company's Kasiya Rutile-Graphite Project (Kasiya or the Project) in Malawi has delivered highly successful results. The testwork focused on optimising the coating process for conversion of Kasiya-derived spherical purified graphite (SPG) to coated spherical purified graphite (CSPG) while maintaining premium performance. The results will assist with ongoing offtake discussions with anode manufacturers. Sovereign is developing Kasiya to potentially become the world's largest and lowest-cost natural graphite producer outside of China.

Figure 1: Natural Flake Graphite Industry Cost Curve For Projects at Prefeasibility Stage or Later

(Sources: See Appendix 1)

Strategic Market Opportunity

The global graphite supply chain is experiencing fundamental realignment following the U.S. Commerce Department's 17 July 2025 announcement of 93.5% preliminary anti-dumping duties on Chinese graphite imports. Combined with existing tariffs, this creates an effective 160% barrier on Chinese graphite, fundamentally altering the economics for battery manufacturers seeking secure, cost-competitive supply chains. China currently controls approximately 75% of global graphite production and 97% of anode material processing, creating critical supply chain vulnerabilities that major battery manufacturers are now actively addressing.

Tesla, Inc. (Tesla) and Panasonic were among companies that opposed the new US tariffs, with Tesla's submission to the U.S. Government stating that U.S. graphite producers have yet to demonstrate the "technical ability to produce commercial quantities" of graphite at the quality and purity required by Tesla and other battery cell manufacturers.

Once developed, Kasiya has the potential to become the world's largest and lowest-cost natural flake graphite producer, offering battery manufacturers a strategic alternative to Chinese supply chains for anode material feedstock. The latest successful coating testwork is a further demonstration of Kasiya's increasing strategic importance.

Latest Testwork Validates Kasiya Graphite's World-Class Quality to Anode Manufacturers

Optimisation testwork conducted by Prographite GmbH (Prographite) has once again demonstrated the exceptional characteristics of Kasiya graphite for CSPG production. The optimisation process successfully achieved target coating specifications and optimised inputs into the coating process while maintaining the premium performance metrics that position Kasiya graphite among the highest-quality sources globally (refer to Announcement "Outstanding Battery Anode Material Produced From Kasiya Graphite" dated 4 September 2024 for previously announced premium performance metrics).

Managing Director and CEO Frank Eagar commented: "Kasiya remains a primary rutile project, but our ability to also produce exceptional CSPG with world-class performance characteristics from our natural graphite concentrate is a further demonstration of the geopolitically strategic nature of Kasiya. These new U.S. tariffs on Chinese graphite highlight the urgent need for reliable, high-quality alternatives. Kasiya's resource scale, long life, potentially lowest-cost non-Chinese producer, combined with our demonstrated technical excellence, positions us perfectly to serve battery manufacturers seeking secure supply chain diversification."

Pitch coating is a standard refinement process where carbon-rich pitch material is applied to spherical graphite particles to create protective layers that enhance battery performance and longevity, turning SPG into CSPG. The latest testwork systematically evaluated pitch content to achieve optimal performance parameters.

Key achievements from the process include:

· Process Efficiency Demonstrated: Coating requirements optimised while maintaining superior CSPG characteristics

· Premium Performance Maintained: All target specifications achieved for discharge capacity (>360mAh/g) and first cycle efficiency (>94%)

· Physical Properties Achieved: Specific surface area (<4m²/g) and tap density (>1.0 g/cm³) specifications met

The electrochemical test results demonstrate the consistently high quality of CSPG produced from Kasiya graphite:

|

Table 1: Electrochemical Half-Cell Testing Results |

|||

|

Pitch Coating Level |

Initial Charge (mAh/g) |

Initial Discharge (mAh/g) |

First Cycle Efficiency (%) |

|

Baseline (100%) |

390 |

369 |

94.64 |

|

Optimised (60%) |

388 |

366 |

94.36 |

The data confirms that Kasiya graphite consistently delivers discharge capacity well above the critical 360mAh/g threshold while achieving first cycle efficiency above 94% - both key specifications for premium-quality natural graphite anode materials.

Customer Engagement Advances with Market Dynamics Creating Strategic Advantage

Initial samples of Kasiya fine flake graphite concentrate have been distributed to leading natural graphite anode producers and anode project developers. These strategic engagements will support the development of offtake agreements while validating market demand for Kasiya's high-quality battery-grade graphite.

The Company continues advancing additional pilot-scale graphite concentrate processing to supply further concentrate material, with planning underway for a larger-scale concentrate processing run. These programs will support expanded customer qualification programs as development advances.

|

Enquiries |

|

|

Frank Eagar, Managing Director & CEO South Africa / Malawi + 27 21 140 3190

Sapan Ghai, CCO London +44 207 478 3900 |

|

|

Nominated Adviser on AIM and Joint Broker |

|

|

SP Angel Corporate Finance LLP |

+44 20 3470 0470 |

|

Ewan Leggat Charlie Bouverat |

|

|

|

|

|

Joint Broker |

|

|

Stifel |

+44 20 7710 7600 |

|

Varun Talwar |

|

|

Ashton Clanfield |

|

|

|

|

|

Buchanan |

+ 44 20 7466 5000 |

Competent Person Statement

The information in this report that relates to Metallurgical Testwork is based on information compiled by Dr Surinder Ghag, PhD., B. Eng, MBA, M.Sc., who is a Member of the Australasian Institute of Mining and Metallurgy (MAusIMM). Dr Ghag is engaged as a consultant by Sovereign Metals Limited. Dr Ghag has sufficient experience, which is relevant to the style of mineralisation and type of deposit under consideration and to the activity which he is undertaking, to qualify as a Competent Person as defined in the 2012 Edition of the 'Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves'. Dr Ghag consents to the inclusion in the report of the matters based on his information in the form and context in which it appears.

The information in this report that relates to Exploration Results is based on information compiled by Mr Malcolm Titley, a Competent Person who is a member of The Australasian Institute of Mining and Metallurgy (AusIMM). Mr Titley consults to Sovereign Metals Limited and is a holder of ordinary shares and unlisted performance rights in Sovereign Metals Limited. Mr Titley has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaken, to qualify as a Competent Person as defined in the 2012 Edition of the 'Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves'. Mr Titley consents to the inclusion in the report of the matters based on his information in the form and context in which it appears.

The information in this announcement that relates to operating costs and graphite marketing is extracted from an announcement dated 22 January 2025, which is available to view at www.sovereignmetals.com.au. Sovereign confirms that: a) it is not aware of any new information or data that materially affects the information included in the original announcement; b) all material assumptions and technical parameters underpinning the Production Target, and related forecast financial information derived from the Production Target included in the original announcement continue to apply and have not materially changed; and c) the form and context in which the relevant Competent Persons' findings are presented in this presentation have not been materially modified from the original announcement.

Forward Looking Statement

This release may include forward-looking statements, which may be identified by words such as "expects", "anticipates", "believes", "projects", "plans", and similar expressions. These forward-looking statements are based on Sovereign's expectations and beliefs concerning future events. Forward looking statements are necessarily subject to risks, uncertainties and other factors, many of which are outside the control of Sovereign, which could cause actual results to differ materially from such statements. There can be no assurance that forward-looking statements will prove to be correct. Sovereign makes no undertaking to subsequently update or revise the forward-looking statements made in this release, to reflect the circumstances or events after the date of that release.

The information contained within this announcement is deemed by Sovereign to constitute inside information as stipulated under the Regulation 2014/596/EU which is part of domestic law pursuant to the Market Abuse (Amendment) (EU Exit) Regulations (SI 2019/310) ("UK MAR"). By the publication of this announcement via a Regulatory Information Service, this inside information (as defined in UK MAR) is now considered to be in the public domain.

APPENDIX 1: FLAKE GRAPHITE OPERATING COST INFORMATION

1. China weighted average C1 cash cost source: Benchmark Mineral Intelligence

2. Cumulative Demand & China graphite production source: S&P Global Market Intelligence

3. Company specific disclosure sources as follows:

|

Company |

Project |

Stage of Development |

C1 Cash Costs (FOB) US$/t |

Steady State Production tpa |

Current Production tpa |

Notes |

Source |

|

Black Rock Mining |

Mahenge |

Financing post DFS |

466 |

89,000 |

- |

Operating costs are for first 10 years therefore prodcution of first 10 years only shown |

Company Announcement: Black Rock Completes FEED and eDFS Update (10 October 2022) |

|

Blencowe Resources |

Orom-Cross |

PFS Complete |

482 |

101,000 |

- |

- |

Company Announcement: Major Milestone as Blencowe Delivers US$482M NPV Pre-Feasibility Study for Orom-Cross Graphite Project (19 July 2022) |

|

Ecograf |

Epanko |

BFS Complete |

508 |

73,000 |

- |

- |

Updated Epanko Ore Reserve (25 July 2024) |

|

Evion |

Maniry |

DFS Complete |

657 |

56,400 |

- |

Production of 56.4ktpa is from year 4. Years 1-3 production is 39ktpa |

BlackEarth Minerals Maniry Graphite Project Definitive Feasibility Study (3 November 2022) |

|

Evolution Energy |

Chilalo |

DFS Complete |

773 |

52,000 |

- |

Operating costs are for first 9 years of produciton |

Company Announcement: FEED and updated DFS confirms Chilalo as a standout high margin, low capex and development-ready graphite project (20 March 2023) |

|

Falcon Energy Materials |

Lola |

Updated DFS Complete |

588 |

92,435 |

- |

- |

SEDAR Filing: Lola Graphite Project NI 43-101 Technical Report - Updated Feasibility Study (7 April 2023) |

|

Focus Graphite |

Lac Knife |

FS Complete |

413 |

50,000 |

- |

Converted from Canadian Dollars to US Dollars based on exchange rate used in source document of 1.00 CAD / 0.736 USD |

Company Announcement: NI 43-101 Technical Report - Feasibility Study Update Lac Knife Graphite Project Québec, Canada (14 April 2023) |

|

Graphite One |

Graphite Creek |

PFS Complete |

1,394 |

51,813 |

- |

Production and costs relate to Graphite Creek Mine and not the proposed graphite manufacturing facility |

Company Announcement: Graphite One Advances its United States Graphite Supply Chain Solution Demonstrating a Pre-tax USD$1.9B NPV (8%), 26.0% IRR and 4.6 Year Payback on its Integrated Project (29 August 2022) |

|

Mineral Commodities |

Skaaland |

Production |

1,434 |

10,000 |

10,000 |

Production based on annual operating target, costs based on latest reported numbers for September 2024 |

Quarterly Activities Report: September 2024 |

|

Mineral Commodities |

Munglinup |

DFS Complete |

491 |

54,000 |

- |

- |

Company Announcement: Robust Munglinup DFS Results Allow MRC to Move to 90% Ownership of Munglinup Graphite Project (8 January 2020) |

|

NextSource Materials |

Molo |

Construction |

541 |

150,000 |

- |

Figures relate to Molo expansion case. |

Company Announcement: Nextsource Materials announces robust feasibility study results for Molo Mine expansion to 150,000 tonnes per annum of Superflake® graphite concentrate (12 December 2023) |

|

NGX |

Malingunde |

PFS Complete |

396 |

52,000 |

- |

- |

Company Presentation: Clean Energy Minerals in Africa (August 2024) |

|

Nouveau Monde Graphite |

Matawinie |

Construction |

443 |

103,328 |

- |

Exchange rate used as per technical report |

Technical Report: Feasibility Study for the Matawinie Property |

|

Renascor |

Siviour |

DFS Complete |

472 |

150,000 |

- |

- |

Company Announcement: Siviour Battery Anode Material Study Results (8 August 2023) |

|

Syrah Resources |

Balama |

Production |

455 |

240,000 |

- |

Production based on Company guidance of 20kt per month production rate. Operating costs based on midpoint of Balama C1 cost (FOB Nacala/Pemba) medium-term guidance of US$430-480 per tonne. |

Company Quarterly Activities Report September 2024 (30 October 2024) |

|

Triton |

Ancuabe |

DFS Complete |

634 |

60,000 |

- |

2023 updates to DFS do not include updated costs and base case production figures. On 9th December 2024, Triton Minerals announced that it had executed a Share Sale and Purchase Agreement with Shandong Yulong Gold Limited for the sale of at least 70% of its interests in the entities that hold the Ancuabe Graphite Project |

Company Announcement: Triton Delivers Robust Ancuabe Definitive Feasibility Study and Declares Maiden Ore Reserve (15 December 2017) |

|

Volt Resources |

Bunyu |

Stage 1 FS Complete |

670 |

24,780 |

- |

Relates to stage 1 development which has had a feasibility study completed |

Company Announcement: Feasibility Study Update for Bunyu Graphite Project Stage 1, Tanzania, delivers significantly improved economics (14 August 2023) |

Notes:

1. Blencowe Resources C1 cash costs calculated as US$499/t operating costs (FOB) less US$17/t royalties as disclosed in the source above

2. South Star Battery Metals Corp.'s Santa Cruz mine not included as FOB costs not disclosed. For reference, operating costs are disclosed as US4396/t from source: Technical Report: Updated Resources and Reserves Assessment and Pre-feasibility Study (18 March 2020)

3. Magnis not included while shares are suspended by the ASX in December 2023

4. Walkabout's Lindi Project not included following appointment of voluntary administrators and Receivers in November 2024

5. Leading Edge Materials Woxna Graphite not included as it is currently under care and maintenance

6. Northern Graphite's Lac des Iles not included due to recent maintenance

7. Talga Group not shown as latest technical study based on integrated anode plant strategy

8. Tirupati Graphite not included due to lack of relevant disclosure

APPENDIX 2: PITCH OPTIMISATION TESTWORK DATA

Prographite produced spherical purified graphite (SPG) with a mean diameter of 17 microns from Kasiya graphite concentrate. Pitch coating in the current testwork was very effective in reducing the Specific Surface Area (SSA) and increasing the tap density of the CSPG relative to SPG, with samples 3,4 and 5 all below 4m2/g SSA and a tap density above 1.0 g/cm3 - Table 2.

The SSA is a key parameter in determining the first cycle efficiency of the anode material - a measure of the percentage of lithium ions used to charge (lithiate) the anode that are discharged (delithiate) from the anode. The rest of the lithium-ions are consumed to form the solid electrolyte interface (SEI) and no longer available for charging/discharging. A full-cell lithium-ion battery (LiB) only has a limited amount of lithium-ions available and therefore maximising the first cycle efficiency is critical to the longevity of the LiB.

The SEI forms a protective layer around the graphite particles, facilitating their use as an effective anode material. Its formation is critical for the ability to use graphite as an anode material. The SEI is generated from lithium compounds, and the consumed lithium-ions are no longer available for charging and discharging a lithium-ion battery. Consequently, excessive SEI formation reduces the lithium-ions available for use in the cell. As a rule, the lower the SSA of the anode material, less lithium-ions are consumed in for ming the SEI and the higher the first cycle efficiency.

|

Table 2 SPG and CSPG Characteristics |

||||||||

|

Sample ID |

Material |

Pitch Level vs Baseline |

SSA (BET) (m2/g) |

Tap Density (g/cm3) |

Particle Size (microns) |

|||

|

D10 |

D50 |

D90 |

D90/D10 |

|||||

|

1 |

SPG |

0 |

7.53 |

0.95 |

11.2 |

17.1 |

26.0 |

2.3 |

|

2 |

CSPG |

0.2 |

4.80 |

0.94 |

12.2 |

18.8 |

28.8 |

2.4 |

|

3 |

CSPG |

0.4 |

3.12 |

1.09 |

11.5 |

17.6 |

26.8 |

2.3 |

|

4 |

CSPG |

0.6 |

2.36 |

1.12 |

11.1 |

17.6 |

27.6 |

2.5 |

|

5 |

CSPG-Baseline |

1.0 |

1.53 |

1.16 |

11.6 |

17.8 |

27.2 |

2.3 |

It is important to note that lithium-ion batteries are complex systems whose optimisation is dependent on many variables across the cell components. In contrast, the half-cell tests used in the current program evaluate the performance of just the anode material in isolation, providing comparative information on anode materials under standard conditions. This data is useful for engagement with anode producers and cell manufacturers but does not describe LiB cell performance, which is more complex.

APPENDIX 3: JORC CODE, 2012 EDITION - TABLE 1

SECTION 1 - SAMPLING TECHNIQUES AND DATA

|

Criteria |

JORC Code explanation |

Commentary |

|

Sampling Techniques |

Nature and quality of sampling (e.g. cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling.

|

Metallurgical Composite Sample: The sample was a composite of multiple hand anger drill samples drilled in 2022 and 2023. Dilling of these samples was within the Kingfisher pit. Clusters of holes were drilled in eight locations. Block 15 Site 1 - PT15BLK00143 - PT15BLK00152 (Hole ID: NSPT0017 - refer ASX Announcement dated 15/03/2022) Block 15 Site 2 - PT15BLK00125 - PT15BLK00142 (Hole ID: KYAC0149 - refer ASX Announcement dated 30/01/2023) Block 15 Site 3 - PT15BLK00103 - PT15BLK00124 (Hole ID: KYAC0142 - refer ASX Announcement dated 30/01/2023) Block 15 Site 4 - PT15BLK00075 - PT15BLK00094, PT15BLK00124, PT15BLK00134 (Hole ID: KYAC0025 - refer ASX Announcement dated 8/09/2022) Block 15 Site 5 - PT15BLK00061 - PT15BLK00074, PT15BLK00099 - PT15BLK00102, PT15BLK00106 - PT15BLK00108 (Hole ID: KYAC0088 - refer ASX Announcement dated 26/10/2022) Block 15 Site 6 - PT15BLK00035 - PT15BLK00060, PT15BLK00076 - PT15BLK00077, PT15BLK00095 - PT15BLK00098, PT15BLK00114 - PT15BLK00117 (Hole ID: KYAC0090 - refer ASX Announcement dated 26/10/2022) Block 15 Site 7 - PT15BLK00013 - PT15BLK00014, PT15BLK00022 - PT15BLK00034 (Hole ID: KYAC0091 - refer ASX Announcement dated 26/10/2022) Block 14 Site 8 - PT15BLK00003 - PT15BLK00012, PT15BLK00015 - PT15BLK00021, PT15BLK00036 - PT15BLK00039 (Hole ID: KYAC0079 - refer ASX Announcement dated 26/10/2022) All samples within the pit shell were added to the composite resulting in a sample of 15,767kg. Samples were processed separately for the eight locations through Sovereign's Malawi metallurgical laboratory. The following workflow was used to generate a pre-concentrate graphite feed: · Wet screen at 2mm to remove oversize · Wet screen at 1mm to remove oversize · Wet screen at 600µm · Wet screen at 45µm to remove -45µm material · Pass +45µm -600µm (fine sand) fraction over laboratory wet shaking table to produce a heavy mineral concentrate, light middling and wet table tailings which is the graphite concentrate. · The +45µm -600µm (fine sand) graphite concentrate and <1000µm >600µm screen fraction were combined to provide flotation feed. The >1000µm fraction was not included. · Flotation was performed at Maelgwyn in Johannesburg. · Fine and coarse gravity tailing samples contain approximately 75%-80% of the graphite present in the feed sample. The majority of the graphite lost is contained in the -45µm fines. |

|

Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used.

|

Placer Consulting (Placer) Resource Geologists have reviewed Standard Operating Procedures (SOPs) for the collection of HA and PT drill samples and found them to be fit for purpose. Drilling and sampling activities are supervised by a suitably qualified Company geologist who is present at all times. All bulk 1-metre drill samples are geologically logged by the geologist at the drill site. The primary metallurgical composite sample is considered representative for this style of mineralisation. |

|

|

Aspects of the determination of mineralisation that are Material to the Public Report. In cases where 'industry standard' work has been done this would be relatively simple (e.g. 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (e.g. submarine nodules) may warrant disclosure of detailed information.

|

HA drilling was used to obtain samples. The bulk metallurgical sample was a composite of selected samples from routine resource drilling. Existing rutile and graphite exploration results were used to determine the 1-metre intervals suitable to contribute to the two bulk sample composites. |

|

|

Drilling Techniques |

Drill type (e.g. core, reverse circulation, open‐hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (e.g. core diameter, triple or standard tube, depth of diamond tails, face‐sampling bit or other type, whether core is oriented and if so, by what method, etc).

|

Hand-auger drilling is completed with 75mm diameter enclosed spiral bits with 1-metrelong steel rods. Each 1m of drill sample is collected into separate sample bags and set aside. The auger bits and flights are cleaned between each metre of sampling to avoid contamination. Placer has reviewed SOPs for hand-auger drilling and found them to be fit for purpose and support the resource classifications as applied to the MRE. |

|

Drill Sample Recovery |

Method of recording and assessing core and chip sample recoveries and results assessed.

|

The configuration of drilling and nature of materials encountered results in negligible sample loss or contamination. Samples are assessed visually for recoveries. Overall, recovery is good. Drilling is ceased when recoveries become poor generally once the water table has been encountered. Auger drilling samples are actively assessed by the geologist onsite for recoveries and contamination. |

|

Measures taken to maximise sample recovery and ensure representative nature of the samples.

|

The Company's trained geologists supervise auger drilling on a 1 team 1 geologist basis and are responsible for monitoring all aspects of the drilling and sampling process.

|

|

|

Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material.

|

No bias related to preferential loss or gain of different materials has occurred. |

|

|

Logging |

Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation mining studies and metallurgical studies.

|

All individual 1-metre auger intervals are geologically logged, recording relevant data to a set template using company codes.

|

|

Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc.) photography.

|

All logging includes lithological features and estimates of basic mineralogy. Logging is generally qualitative. |

|

|

The total length and percentage of the relevant intersection logged

|

100% of samples are geologically logged. |

|

|

Sub-sampling techniques and sample preparation |

If core, whether cut or sawn and whether quarter, half or all core taken.

|

Not applicable - no core drilling conducted.

|

|

If non-core, whether riffled, tube sampled, rotary split, etc. and whether sampled wet or dry. |

Primary individual 1-metre samples from all HA and PT holes drilled are sun dried, homogenised and riffle split.

|

|

|

For all sample types, the nature, quality and appropriateness of the sample preparation technique.

|

Metallurgical Composite Sample: Full length of the Hand Auger Holes were processed in total 15,767kg. Graphite concentrate sent to Maelgwyn was ~4,800kg |

|

|

Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples.

|

The sample preparation techniques and QA/QC protocols are considered appropriate for the nature of this test-work.

|

|

|

Measures taken to ensure that the sampling is representative of the in situ material collected, including for instance results for field duplicate/second-half sampling.

|

The sampling best represents the material in situ. |

|

|

Whether sample sizes are appropriate to the grain size of the material being sampled.

|

The sample size is considered appropriate for the nature of the test-work. |

|

|

Quality of assay data and laboratory tests |

The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. |

Metallurgical Composite Sample: The following workflow was used to generate a graphite product; · Rougher graphite flotation · Polishing grind of rougher graphite concentrate · Primary cleaner flotation milled rougher concentrate · Attrition milling of primary cleaner concentrate · Secondary cleaning of attritioned primary cleaner concentrate · Attrition milling of secondary cleaner concentrate · Tertiary cleaner flotation of attritioned secondary cleaner concentrate · Final concentrate dewatering, drying and sizing |

|

For geophysical tools, spectrometers, handheld XRF instruments, etc., the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc.

|

Acceptable levels of accuracy and precision have been established. No handheld methods are used for quantitative determination.

|

|

|

Nature of quality control procedures adopted (e.g. standards, blanks, duplicate, external laboratory checks) and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established.

|

Acceptable levels of accuracy and precision have been established in the preparation of the bulk sample composites. |

|

|

Verification of sampling & assaying |

The verification of significant intersections by either independent or alternative company personnel.

|

No drilling intersections are being reported. |

|

The use of twinned holes.

|

No twin holes completed in this program.

|

|

|

Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. |

All data was collected initially on paper logging sheets and codified to the Company's templates. This data was hand entered to spreadsheets and validated by Company geologists.

|

|

|

Discuss any adjustment to assay data.

|

No adjustment to assay data has been made.

|

|

|

Location of data points |

Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation.

|

A Trimble R2 Differential GPS is used to pick up the collars. Daily capture at a registered reference marker ensures equipment remains in calibration. No downhole surveying is completed. Given the vertical nature and shallow depths of the holes, drill hole deviation is not considered to significantly affect the downhole location of samples. |

|

Specification of the grid system used. |

WGS84 UTM Zone 36 South. |

|

|

Quality and adequacy of topographic control. |

DGPS pickups are considered to be high quality topographic control measures. |

|

|

Data spacing & distribution |

Data spacing for reporting of Exploration Results. |

Metallurgical Composite Sample: The hand-auger holes contributing to this metallurgical were selected from pit area Kingfisher and broadly represent early years of mining as contemplated in the OPFS (Approximately the first three years).

It is deemed that these holes should be broadly representative of the mineralisation style in the general area.

|

|

Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. |

Not applicable, no Mineral Resource or Ore Reserve estimations are covered by new data in this report. |

|

|

Whether sample compositing has been applied. |

Metallurgical Composite Sample: The sample was composited as described under Sampling Techniques in this Table 1.

|

|

|

Orientation of data in relation to geological structure |

Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known considering the deposit type

|

No bias attributable to orientation of sampling has been identified. |

|

If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material.

|

All holes were drilled vertically as the nature of the mineralisation is horizontal. No bias attributable to orientation of drilling has been identified. |

|

|

Sample security |

The measures taken to ensure sample security |

Samples are stored in secure storage from the time of drilling, through gathering, compositing and analysis. The samples are sealed as soon as site preparation is complete.

A reputable international transport company with shipment tracking enables a chain of custody to be maintained while the samples move from Malawi to Johannesburg. Samples are again securely stored once they arrive and are processed at Maelgwyn.

Graphite concentrate samples were shipped to German laboratories using a reputable international transport company with shipment tracking to enable a chain of custody to be maintained while the samples moved from Johannesburg to Germany. Concentrate samples are securely stored once they arrive and are processed in Germany.

At each point of the sample workflow the samples are inspected by a company representative to monitor sample condition. Each laboratory confirms the integrity of the samples upon receipt. |

|

Audits or reviews |

The results of any audits or reviews of sampling techniques and data

|

It is considered by the Company that industry best practice methods have been employed at all stages of the exploration.

Malawi Field and Laboratory visits have been completed by Richard Stockwell in May 2022. A high standard of operation, procedure and personnel was observed and reported.

|

SECTION 2 - REPORTING OF EXPLORATION RESULTS

|

Criteria |

Explanation |

Commentary |

|

Mineral tenement & land tenure status |

Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environment settings. |

The Company owns 100% of the following Exploration Licences (ELs) under the Mines and Minerals Act 2019 (Malawi), held in the Company's wholly-owned, Malawi-registered subsidiaries: EL0609, EL0582, EL0492, EL0528, EL0545, EL0561, EL0657 and EL0710.

A 5% royalty is payable to the government upon mining and a 2% of net profit royalty is payable to the original project vendor.

No significant native vegetation or reserves exist in the area. The region is intensively cultivated for agricultural crops. |

|

The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area. |

The tenements are in good standing and no known impediments to exploration or mining exist. |

|

|

Exploration done by other parties

|

Acknowledgement and appraisal of exploration by other parties. |

Sovereign Metals Limited is a first-mover in the discovery and definition of residual rutile and graphite deposits in Malawi. |

|

Geology |

Deposit type, geological setting and style of mineralisation |

The rutile deposit type is considered a residual placer formed by the intense weathering of rutile-rich basement paragneisses and variable enrichment by eluvial processes.

Rutile occurs in a mostly topographically flat area west of Malawi's capital, known as the Lilongwe Plain, where a deep tropical weathering profile is preserved. A typical profile from top to base is generally soil ("SOIL" 0-1m) ferruginous pedolith ("FERP", 1-4m), mottled zone ("MOTT", 4-7m), pallid saprolite ("PSAP", 7-9m), saprolite ("SAPL", 9-25m), saprock ("SAPR", 25-35m) and fresh rock ("FRESH" >35m).

The low-grade graphite mineralisation occurs as multiple bands of graphite gneisses, hosted within a broader Proterozoic paragneiss package. In the Kasiya areas specifically, the preserved weathering profile hosts significant vertical thicknesses from near surface of graphite mineralisation. |

|

Drill hole information |

A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes: easting and northings of the drill hole collar; elevation or RL (Reduced Level-elevation above sea level in metres of the drill hole collar); dip and azimuth of the hole; down hole length and interception depth; and hole length |

All intercepts relating to the Kasiya Deposit have been included in public releases during each phase of exploration and in this report. Releases included all collar and composite data and these can be viewed on the Company website. There are no further drill hole results that are considered material to the understanding of the exploration results. Identification of the broad zone of mineralisation is made via multiple intersections of drill holes and to list them all would not give the reader any further clarification of the distribution of mineralisation throughout the deposit.

|

|

If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case |

No information has been excluded. |

|

|

Data aggregation methods |

In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (e.g. cutting of high-grades) and cut-off grades are usually Material and should be stated. |

No data aggregation was required. |

|

Where aggregate intercepts incorporate short lengths of high-grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. |

No data aggregation was required. |

|

|

The assumptions used for any reporting of metal equivalent values should be clearly stated. |

Not applicable |

|

|

Relationship between mineralisation widths & intercept lengths |

These relationships are particularly important in the reporting of Exploration Results. |

The mineralisation has been released by weathering of the underlying, layered gneissic bedrock that broadly trends NE-SW at Kasiya North and N-S at Kasiya South. It lies in a laterally extensive superficial blanket with high-grade zones reflecting the broad bedrock strike orientation of ~045° in the North of Kasiya and 360° in the South of Kasiya. No drilling intercepts are being reported. |

|

If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported. |

The mineralisation is laterally extensive where the entire weathering profile is preserved and not significantly eroded. Minor removal of the mineralised profile has occurred where alluvial channels cut the surface of the deposit. These areas are adequately defined by the drilling pattern and topographical control for the resource estimate. |

|

|

If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (e.g. 'down hole length, true width not known'. |

No drilling intercepts are being reported. |

|

|

Diagrams |

Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported. These should include, but not be limited to a plan view of the drill collar locations and appropriate sectional views. |

The original exploration results and plan view of the drill holes for the samples used in relation to the metallurgical composite test work conducted in this announcement, are included in Sovereign's announcements dated 15 March 2022, 8 September 2022, 26 October 2022 and 30 January 2023.

These announcements are accessible on the Company and ASX websites. |

|

Balanced reporting |

Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high-grades and/or widths should be practiced to avoid misleading reporting of exploration results. |

All results are included in this report and in previous releases. These are accessible on the Company's webpage. |

|

Other substantive exploration data |

Other exploration data, if meaningful and material, should be reported including (but not limited to: geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. |

Limited lateritic duricrust has been variably developed at Kasiya, as is customary in tropical highland areas subjected to seasonal wet/dry cycles. Lithological logs record drilling refusal in just under 2% of the HA/PT drill database. No drilling refusal was recorded above the saprock interface by AC drilling. Sample quality (representivity) is established by geostatistical analysis of comparable sample intervals.

|

|

Further work |

The nature and scale of planned further work (e.g. test for lateral extensions or depth extensions or large-scale step-out drilling). |

Having completed an OPFS in January 2025, the Company is working towards completing a definitive feasibility study. |

|

Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. |

Refer to diagrams and plan views disclosed in previous announcements. These are accessible on the Company's website as discussed above. |

RNS may use your IP address to confirm compliance with the terms and conditions, to analyse how you engage with the information contained in this communication, and to share such analysis on an anonymised basis with others as part of our commercial services. For further information about how RNS and the London Stock Exchange use the personal data you provide us, please see our Privacy Policy.